- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

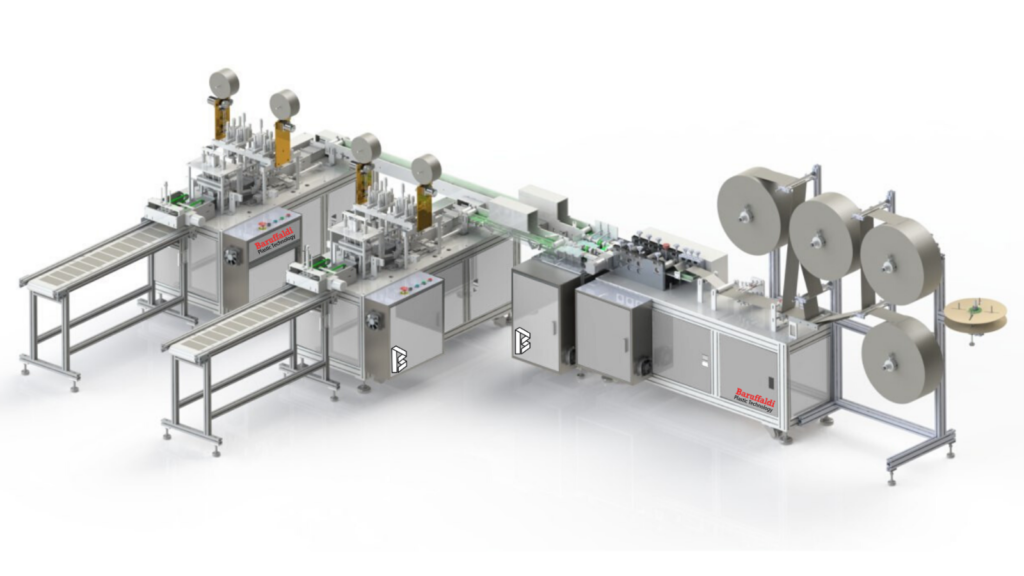

From the evolution of Baruffaldi Plastic Technology know-how, the first fully automatic production line for surgical face masks was born. “ We decided to apply our technical knowledge to the needs of this hard and difficult period, keeping low the costs of the finished product thanks to a high productivity machine” – explains the CEO Alberto Dosi.

With this new line called MM100, it is possible to produce 100-120 surgical masks in tissue not tissue (TNT) per minute. These masks have three layers: an external one in Spunbond TNT that gives mechanical resistance to the mask; an intermediate one in Meltblown TNT that works as a filter and an internal one in Spunbond TNT that protects the face. These three layers are welded by an exclusive ultrasonic welding system. In this way the mask is soft, has a good air permeability and an excellent filtration of pathogens and dust, according to the surgical norms and technical requirements.

The full project has been developed in smart working in a record time and became part of the Baruffaldi’s catalogue. The company was already present in the biomedical field with machines for the production of respirator’s pipes. The brand Baruffaldi is well-known all over the world; the company exports almost the 90% of its production, it is therefore natural that the surgical face masks production line MM100 is having a great success both in Italy, where in mid-June the first line will be delivered, and abroad, where there will be other orders soon, proving once again the excellence of the Dosi Group in the fields of mechanics and automation.

Innovation has always been in the DNA of the company tradition, the production team is driven and involved in the project, with an enthusiasm that will contribute to the customer satisfaction, which is guaranteed also thanks to the high knowledge of the technicians that will provide an efficient after-sales assistance.