- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

During 2022, Baruffaldi technicians studied and designed various upgrades of the CapInserter, our automatic machine specifically developed for the off-line assembly of aluminum and steel roller shutters, with lengths between 500 and 6500 mm.

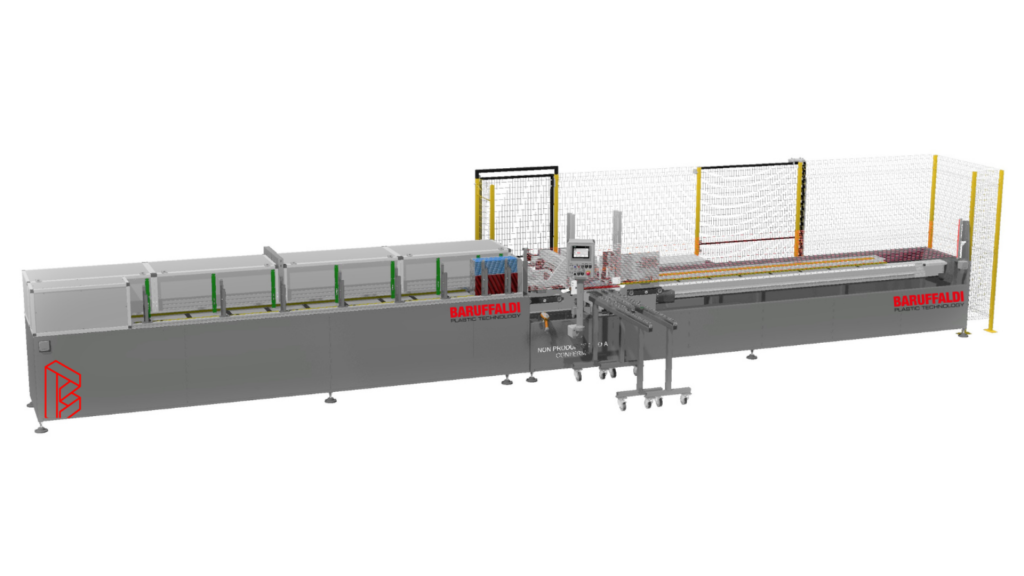

The CapInserter, which has long been successfully sold worldwide, is extremely flexible, as it can be made up only of the units that the customer needs. It it is offered with three different types of feed in tables of variable length according to production needs and investment budget. The basic model CAP-ST consists of an assembly table for pre-assembled roller shutters, the CAP-CV is equipped with a vertical feed in table for cut-to-length profiles and the CAP-CO is equipped with a horizontal feed in table for slat packs to be cut to length or already cut.

The first upgrade concerns the horizontal feed in table, where the operator manually loads a slat pack for the production and a spare one. The machine automatically processes the single slats, cuts them to length and unloads the profiles that are too short to be processed on the opposite side of the machine. Thanks to an important upgrade of motors, inserters and haul off, now this type of feed in table is much faster. Moreover, a horizontal feed in table for slat packs already cut to length has been designed specifically for profiling customers. In this case, the machine assembles mats of 3 or 4 profiles at a time, consequently the production speed is extremely high, about 1 m2 per minute, and completely synchronized with the speed of the profiling line.

Depending on how the customer purchases the slat packs, i.e., already slotted or not and already cut to length or not, it is possible to set up the CapInserter with a latest generation high-speed electro-mechanical punching machine for slotting the slats and/or a new saw with servo-driven transversal movement, capable of guaranteeing a great cutting quality, while also maintaining a high process speed. The CAP-CO complete with the saw has a productivity of about 3 m2 in 2 minutes and 30.

After that, the single or the pre-assembled slats, already slotted and cut-to-length, are automatically assembled to form the roller shutter through a precise and fast assembling system, which also guarantees the integrity of the product. The assembly table, of variable length according to the customer’s request, consists of two cap insertion heads, one fixed and the other mobile for variable slats lengths, which automatically insert the plastic caps at the ends of the roller shutter. Then the caps are blocked in the profile by means of metal clips (single or double) or punching (from above or below or both) according to the customer’s preference.

The CapInserter can also be equipped with a semi-automatic rolling unit, which automatically grips the roller shutter in process and rolls it up.

The big innovation of 2022 is the addition of two heads, positioned before the cap insertion heads, for the creation of the space for the caps in the high-density polyurethane foam to profiles of all sizes. Today Baruffaldi gives the customer the possibility to assemble roller shutters with both mini and maxi profiles as well as low- and high-density PU with a single machine and using the same plastic caps. This innovation has met with a lot of interest especially in Italy, where aluminum roller shutters with high density PU are experiencing great success, and 7 machines have already been sold and will go into operation during 2023.

The software has also been redesigned and integrated with all the variants in order to be able to assemble roller shutters of different lengths, also entering several programs at a time, and to manage the metal terminal at the end of the roller shutter and the intermediate bolt. Lastly, the CapInserter can be equipped with both a scanner for barcodes reading and automatic entry of production data into the operator panel and with the Industry 4.0 package.

Both CAP-CV and CAP-CO are automatic machines which, given the great autonomy of the feed in tables and the high degree of automation, can be managed by a single operator who, during the assembly phase, can, in addition to checking the roller shutter quality, also packs the finished roller shutters.

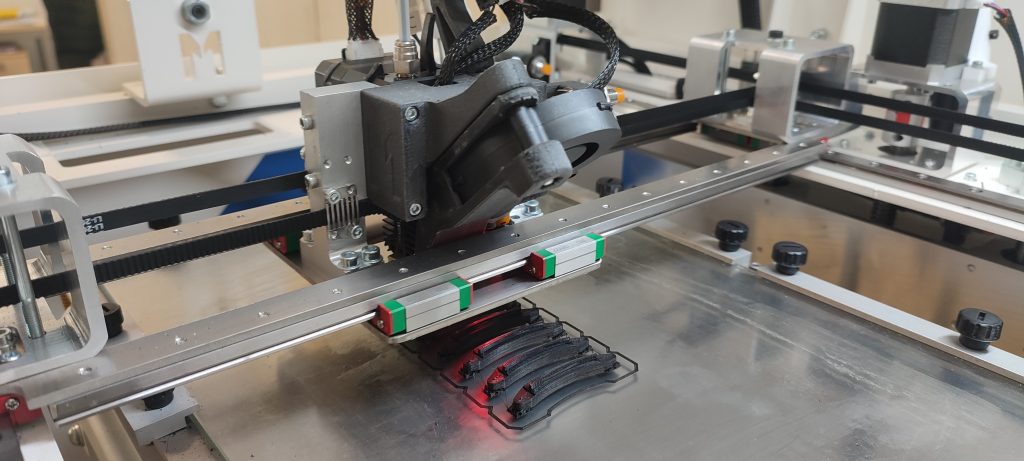

Baruffaldi technical office collaborates with the customer to define the best shape of the plastic caps also using 3D printing for the additive manufacturing of prototype caps for the preliminary tests, to verify their functionality and tightness.

In addition to the machine, we also supply the vibrating bowls that assemble the cap loaders to be inserted into the cap insertion heads of the CapInserter.

Thanks to the upgrades developed during 2022, CapInserter is now an automatic machine with a high technological level, modular, reliable and with high productivity. “Our mission – says the CEO Mr. Alberto Dosi – is to become the market reference in the field of assembling machines for low, medium and high-density aluminum roller shutters in terms of performance and technology, offering our customers cutting-edge solutions which, thanks to their modularity and versatility, meet their needs in terms of productivity, quality, safety and even sustainability.”