- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

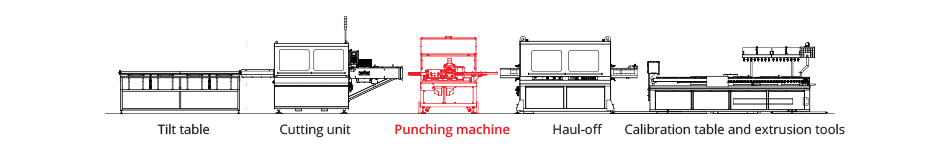

Baruffaldi rotary punching machine is a stand-alone unit that can be personalised to meet customers’requirements. It can be positioned directly after the haul-off in the extrusion line, or used off-line, coupled with the special automatic feed-in table. The structure consists of a sturdy, electro-welded steel frame, which is height adjustable, and of a punching head that can rotate from 0 to 90°.

The punch tool set is made up of a top roller with punches and a lower roller with holes (die), that rotate synchronously as they are driven by a single brushless motor. It is possible to vary the punching speed with high accuracy.

The punch tool sets are made of special hardened and tempered steel and are conceived of for quick and easy changeover. Each punch tool set is designed according to the specific profile punching pattern.

PR/1T is a single-head rotary punching machine.

It is fast and versatile: it can punch a wide variety of technical profiles extruded at speeds of up to 30 m/min. It features a set of quick changeover rotary punching tools and can be used in-line or off-line.

The rotary punching unit can also be supplied with two heads for angle profiles. (PR/2T).

The two rotary punching units can be brought closer to each other through a manual adjustment system and the heads can be adjusted so that the punches are always at 90° with respect to the surface to be punched. To guide the profile during the punching process the machine is equipped with special guides. It also includes a scrap discharge container to collect the punch outs.

The machine’s electrical system is housed in an electrical cabinet located on the back of the unit. The brushless motor guarantees a low noise level and the reduction of acoustic emissions for a safe and healthy working environment.