- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

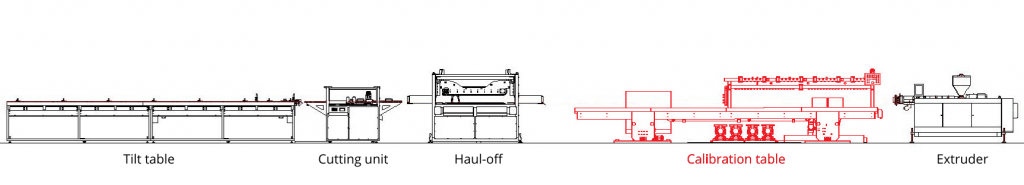

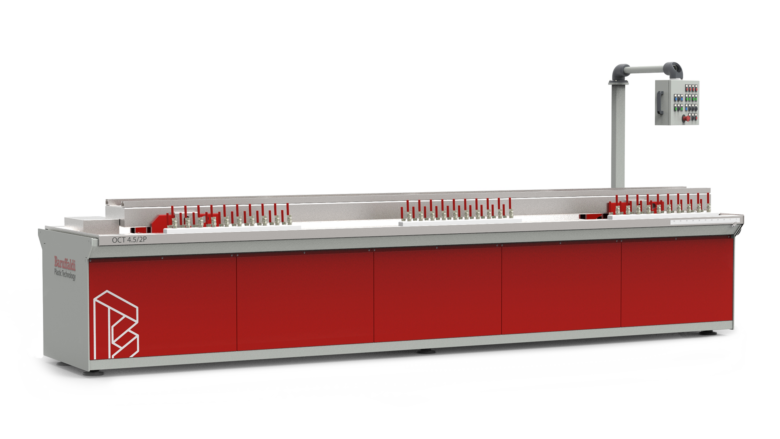

Our new generation modular calibration tables are conceived with energy recycling circuits for the maximum reduction of energy consumption.

They are available in different lengths (from 3 to 20 m) and with a number of pumps according to the specific applications. They stand out for their sturdiness, solidity and quality of materials, being entirely made of steel.

They are equipped with a (stainless steel) water collection bath of the same size as the frame, modular (stainless steel) water and vacuum distributors with manifolds, vacuum on pumps fixed to independent frames, extractable sideways and mounted on a different rails system to avoid the transmission of vibrations.

Motor-driven longitudinal movement on rails and vertical movement. Manual or motor-driven plane translation and tilting movements (optional).

Motor-driven transversal adjustment. Baruffaldi has developed two different kinds of calibration tables suitable for a wide range of profile sizes and geometries.

The whole calibration table moves longitudinally on rails. The vacuum pumps are assembled onto independent frames, that can be extracted sideways, to avoid the transmission of vibrations during the process.

This type of calibration table is part of our standard Omnia extrusion line. Its longitudinal movements affect only the tank with the calibrators.

The frame, resting on feet, is fixed, and only the water bath moves longitudinally. Our calibration tables are made according to the specific production needs of our customers: they are equipped with independent energy saving systems and are available also with a built in heat exchange unit.

Functionality, manufacturing accuracy and customisation are the distinctive features of our machines.