- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

These automatic machines are designed to drill holes into PVC profiles directly in the extrusion line. They can be manufactured as stand-alone machines, to be placed between the haul-off and cutting device or as units to be positioned on the calibration table.

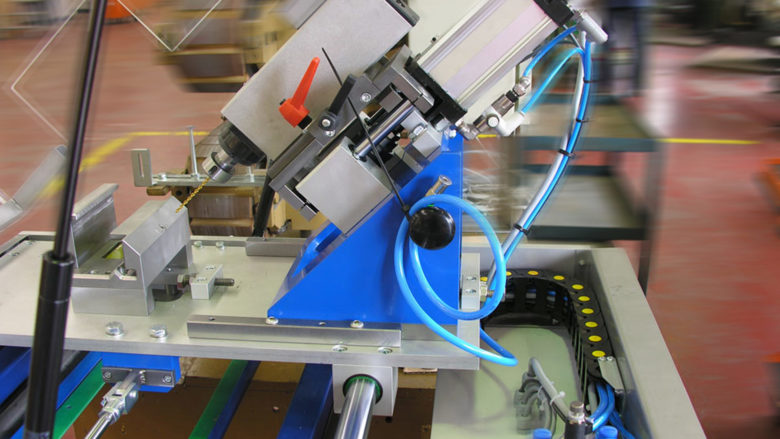

The drilling is carried out by one or more milling heads, mounted on vertical slides that can also be inclined.

The frame of the machine is fitted with adjustable supports. There is enough space between the frame and the shop floor to allow the machine to be lifted with a forklift truck.

In-line drilling machine, to drill holes on rigid PVC profiles, positioned at the end of the calibration table.

Specifically required by building industry companies.

It is also equipped with a dust suction device to obtain a clean and ready-to-sell product.

Independent in-line or off-line drilling machine with 4 heads to achieve 4 holes on the walls of PVC panels.

Specifically required by building industry companies.

Independent in-line or off-line pipe-drilling machine that processes pipes up to 110 mm in diameter. Three drilling heads are positioned at angles so that the overall angle among them is 120°.

It is available in both in-line or off-line versions with manual or automatic pipe feeding system and with related feed out support.

One of its main application is in the drainage pipe industry.